Installing a

— glued wooden floor

Gluing your wooden floor offers a number of advantages. Your floor comes directly on the screed, making it particularly stable and quiet. The installation does require some dexterity. We are happy to give you the most important points of attention.

Choose the right adhesive

A good quality of adhesive is indispensable for the best result. Keep in mind:

- the nature and flatness of the surface

- the properties of the wooden floor: the type of wood, the width, thickness and type of the elements, the moisture sensitivity of the wood, the presence of a finishing layer, ...

- the presence of underfloor heating

- the placement properties

Check the substrate

Before you proceed to the glued installation of your wooden floor, check whether the screed is of good quality. In other words: is there a solid cement screed that consists of 300 to 320 kg of cement per cubic meter of sand? Then you can immediately glue the planks to the screed.

If the quality of the screed is not sufficient, you can use plywood or OSB boards of 12 or 18 mm as an intermediate floor. Glue the chipboards to the floor and nail them in strips of 15 cm (horizontal and vertical) into the sand cement screed. It is best to lay the boards in half-brick bond. If the sand cement screed is of very poor quality, you can plug the plates into the concrete. Gluing is then not necessary.

This is how you create a subfloor from chipboard. You can now fully glue your wooden floor on it. You apply parquet glue evenly to the entire underside of the parts, not in tongue and groove and ends. Every meter you fix the planks with an angled nail on the long side to prevent them from shifting before the glue has fully hardened.

When installing your floor

— please take the following into consideration

Before installation

Let the boards acclimatize for 72 hours in closed packaging in the room where you wish to install them.Put them down horizontally and flat.

Adjustment of the doors

Check with the height of your possible subfloor and wooden flooring whether your doors can still be opened and closed.

Application of vapour retardant PE-foil

The seams should be absolutely closed. Apply the foil up to skirting height behind the skirting board.

Provide expansion joints

If the floor is wider than 6 m and/or longer than 12 m, provide expansion joints of +/- 11 mm.

Use spacers

They are necessary to maintain an equal distance between the wooden flooring and the wall. Provide a swelling seam of 11 mm all around the floor. Remove the spacers after 24 hours.

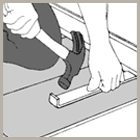

The scale iron

Use the scale iron to connect the ends of the boards.

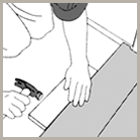

The stop buffer

Use it when tapping the boards to prevent damage to the panels.

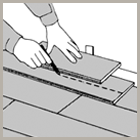

Fitting the last row

Install the boards with the decor side at the bottom and the groove against the wall. Now mark off the correct distance and cut off the plank. Do not forget to provide the swelling seam of 11 mm.